To meet the ever growing demand for fully automated end of line systems, which increasingly require robotic solutions, Endoline Machinery Ltd has created a sister company called Endoline Robotics Limited (ERL) while also forging a strategic partnership with Fanuc Robotics.

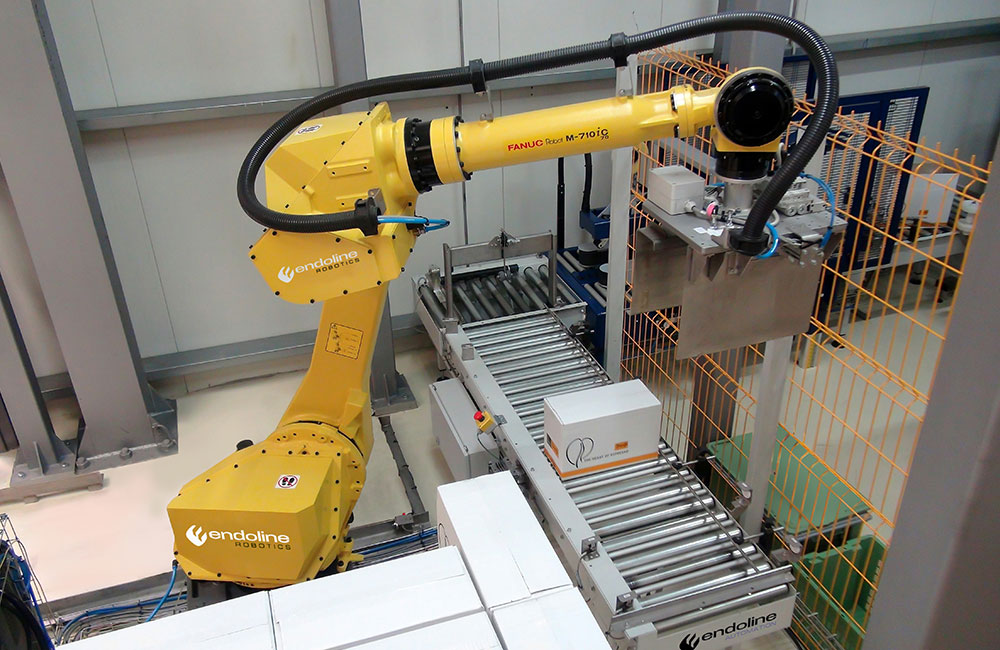

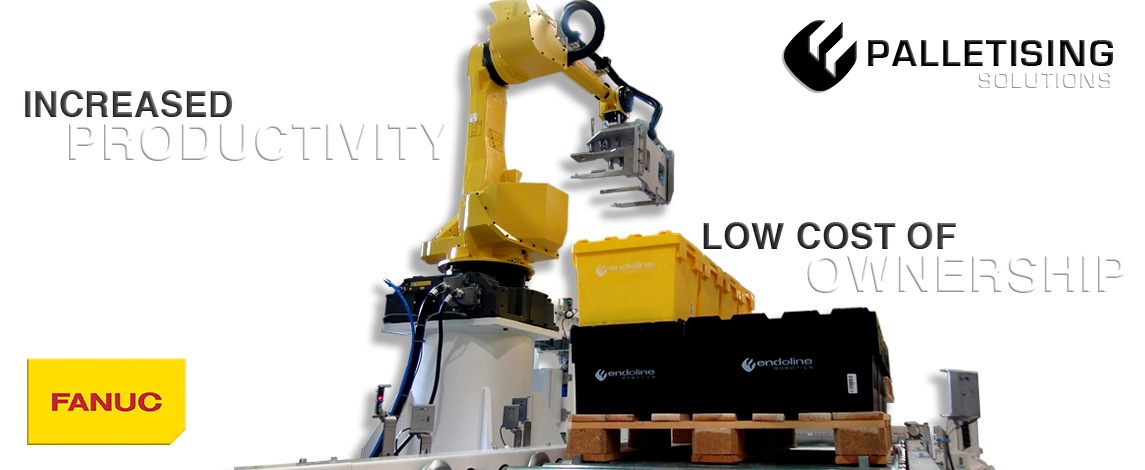

The move is designed to reinforce Endoline’s reputation as a provider of case erecting and sealing automation and, through the strength of the Fanuc brand, the company will now manage the installation of robotic palletising systems under the umbrella of ERL.

“Our ability to engineer customised, fully automatic case erecting and sealing solutions underpins our reputation in the market,” says Andrew Yates, MD of ERL.

“Through our relationship with leading global food manufacturers we have become increasingly aware of the demand for robotic integration, particularly as companies move away from using manual labour.

COMMITTED TO UK BUSINESS

“The decision to partner with Fanuc and launch a sister company dedicated to robotic palletising equipment, illustrates a progressive period in our almost 40 year history,” he continues. “While we have developed the company and built up a solid export business, we are committed to the UK and creating solutions which directly meet our customers needs.”