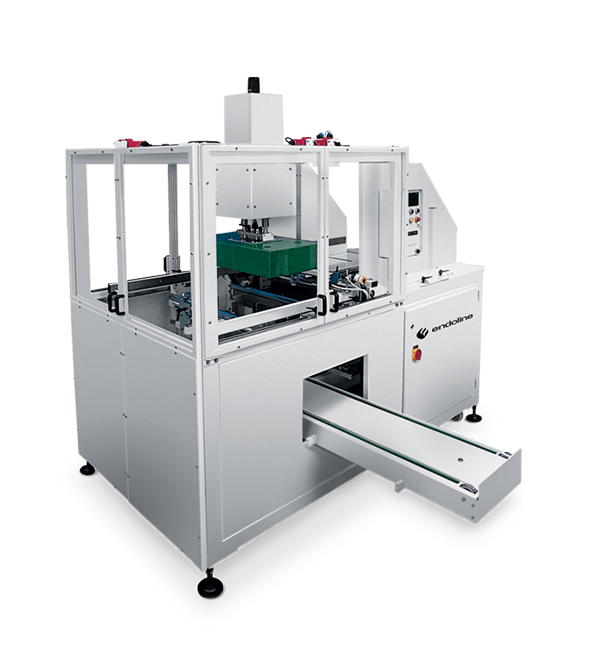

500 Series – Fully Automatic Hot Melt Glue Tray Erector

The type 500 series tray erectors have a number of unique features that combine to make it extremely efficient, reliable and versatile while handling a wide variety of tray sizes and styles. The tray erector is designed to be flexible enough to operate on a wide range of tray sizes and styles up to 30 per minute. The machines can hold approximately 200 ‘B’ flute blanks which can be replenished during operation, therefore keeping the machine running smoothly.

SPEED

Up to 30 trays per minute.

HOT MELT GLUE

The 500 series uses glue systems to seal the trays using hot melt glue. Endoline use Nordson Pro-Blue glue systems as standard, offering high quality and efficency. Other glue systems are available on request.

MACHINE FINISH

Mild steel, powder coated white (RAL9010) or stainless steel.

TRAY DIMENSIONS

The 500 series can operate on a wide range of tray styles and can handle trays between 200-800mm length, 200-920mm width and 40-150mm height (open).

BESPOKE OPTIONS

Any of Endoline’s machines can be modified or customise designed to suit your specification, if you can’t find exactly what you want then contact Endoline and a Sales Engineer will discuss your requirements with you in full.

Key Factors

Watch the video

*The video shown is for illustrative purposes only and may differ according to order specification.

Summary

RELATED ITEMS