Endoline Automation to showcase eco-friendly sealing solutions at PPMA 2022

At PPMA 2022 (Stand D50) Endoline Automation will highlight the sustainable features of its end-of-line packaging systems, and eco-friendly sealing options in a bid to support manufacturers who are seeking packaging machinery which will aid net zero objectives.

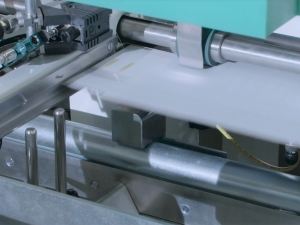

Responding to calls for sustainable sealing solutions which reduce the use of plastic, Endoline will showcase its 248 Fully Automatic High Speed Case Erector, which has been engineered to seal cases with hot melt glue rather than tape.

While utilising glue sealing alternatives can significantly reduce plastic consumption for manufactures, it also helps drive down material waste as 2 square inches of adhesive glue will close an average size box compared with over 200 square inches of tape.

Further responding to demands to create eco-friendly sealing solutions, Endoline will also highlight recyclable Kraft tape as an additional eco-friendly sealing alternative.

The British manufacturer, who has been creating end-of-line machinery solutions for over 40 years, will also demonstrate the eco credentials across its case erecting and sealing system ranges. Including power saving features which reduce energy consumption, and the use of servo drives to significantly drive down noise emissions whilst only using power while operating.

“We are seeing growing calls from customers for OEMs to demonstrate their sustainable credentials, and this is driving innovation in the packaging machinery space,” comments Andrew Yates, Managing Director of Endoline Automation.

“While our systems have been re-engineered over the years to reduce energy consumption and cut emissions to support the environmental objectives of our customers, we are looking at ways to help them decrease plastic use and waste even further by offering eco-friendly sealing alternatives.”

To see the glue sealing 248 Fully Automatic High Speed Case Erector in operation and understand how Endoline Automation can support a manufacturer’s sustainability drives visit Stand D50.

Endoline has engineered its 248 Fully Automatic High Speed Case Erector to seal cases with hot melt glue rather than tape

Endoline offer glue sealing alternatives that can significantly reduce plastic consumption for manufactures