Interpack 2023: Endoline Robotics to demonstrate fast and versatile Case Packer. Stand E34, Hall 8b

We are pleased to announce we will have representatives from Endoline Robotics at Interpack 2023.

Interpack is the world’s largest and most important trade fair for the packaging sector and related process industries. With 2583 exhibitors from 55 countries, for packaging machinery, there’s simply nothing as big as interpack!

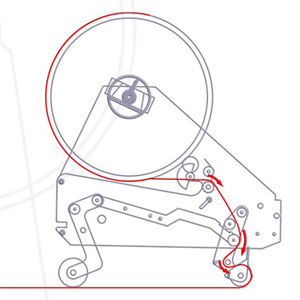

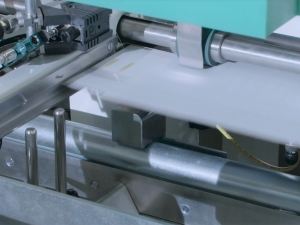

Showcasing the Delta 3000 Top Loading Case Packer at the forthcoming Interpack, Endoline Robotics (stand E34, Hall 8b) is set to demonstrate the benefits of automation, and the quick return on investment which can be achieved.

Like the company’s palletising systems, the first range launched under the Endoline Robotics division, each case packer is designed and built by Endoline to accommodate various packaging types: bottles, pillow packs, SRP packaging etc.

With a variable throughput speed depending on the application, the case packing systems can also be suited to match a product’s shape and orientation. As with all Endoline systems, the case packer is modular in design and can be fully integrated into existing production lines.

Each Endoline system can also be integrated into a manufacturer’s Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES) to provide a turnkey operation with real-time data reporting capabilities. Through OEM partnerships, Endoline are also able to integrate additional elements into a line, including stretch wrapping, conveyoring and labelling systems making the line seamless and fully automated.

If you are visiting Interpack and would like to meet with us please send us an email to arrange an appointment.