Endoline Machinery

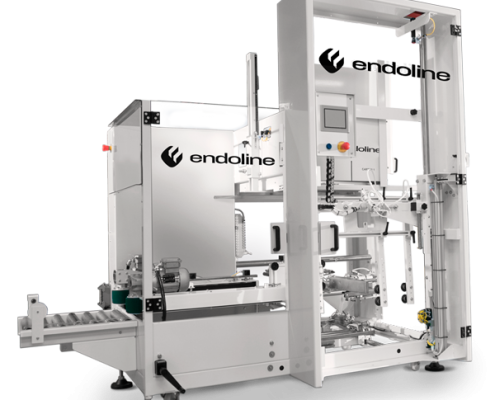

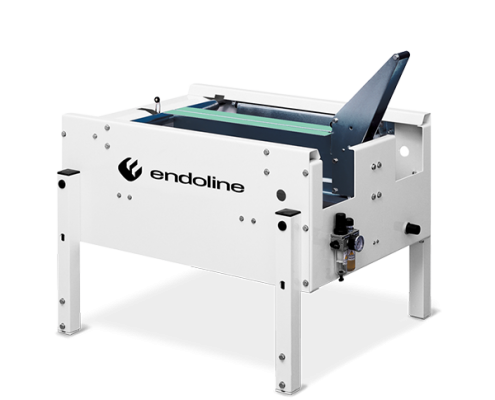

Endoline Automation specialise in the design, manufacture and installation of high quality end of line packaging machinery including Case Erectors, Case Packers & Case Sealers. For over 40 years Endoline’s business has developed from designing and manufacturing small case taping machines to its position today as a leading UK manufacturer and worldwide supplier of end-of-line packaging machines and systems.

FOLLOW US:

Latest News

Endoline Automation expands into Germany with BBVerpackungsmaschinen partnershipJune 30, 2025 - 9:54 am

Endoline Automation expands into Germany with BBVerpackungsmaschinen partnershipJune 30, 2025 - 9:54 am Endoline Returns to CFIA Rennes After Successful 2024 Debut Booth 10–E4February 27, 2025 - 11:31 am

Endoline Returns to CFIA Rennes After Successful 2024 Debut Booth 10–E4February 27, 2025 - 11:31 am Endoline Automation Strengthens Global Foothold Through Exporting SuccessFebruary 6, 2025 - 8:37 am

Endoline Automation Strengthens Global Foothold Through Exporting SuccessFebruary 6, 2025 - 8:37 am

ENDOLINE AUTOMATION

Business Hours

Mon-Thurs:- 08:30 - 17:00

Friday:- 08:30 - 15:00

Endoline Machinery Ltd,

Stratton Business Park, London Road,Biggleswade, Bedfordshire, SG18 8QB

Email us : sales@endoline-automation.com

Call us now :+44 (0) 1767 316422